Excellent performance of the heat shrinkable film

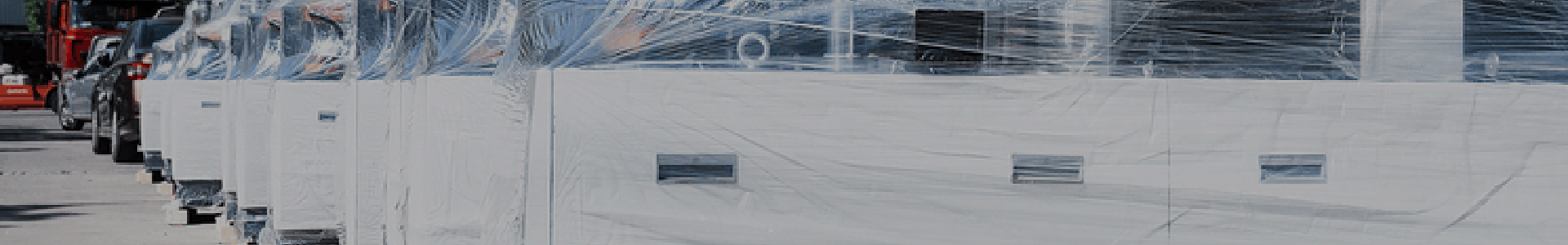

The heat-shrinkable film is a thermoplastic film that is stretched and oriented during the production process and shrinks by heat during use. The principle of the heat-shrinkable film is making use of the energy of the film stretched in the longitudinal or transverse direction in the high-elastic state stored in the film and the memory effect of thermoplastics on the shape before bidirectional or unidirectional stretching. It uses the function of restoring the shape before stretching to achieve the purpose of packaging. Heat shrink packaging, using shrink wrap machines, is a packaging method widely used in commodity packaging, which can be used to package various types of products. It has the characteristics of transparency, container, sealing, moisture-proof, simple process and equipment, low packaging cost and various packaging methods, which are favored by merchants and consumers. As manufacturers increasingly pursue differentiated product competition, the market for heat shrinkable film labels for packaging food, beverages and other consumer foods has developed rapidly.

The shrink film is a good film packaging material, it has the following advantages. 1. Beautiful appearance and close to the product, so it is also called skin-packing, which is suitable for all different types of product packaging. 2. Good protection. You can pack a variety of products in a heat shrinkable packaging bag. Preventing the loss of individual small commodities is also convenient for customers to carry. 3. It is especially suitable for packaging of precision instruments and high-precision electronic components. 4. Choose different resins and formulas. It can produce different mechanical strengths and heat-shrinkable films. It can be used for inner packaging with lower strength and lower weight, and can also be used for mechanical products for containers with higher strength, transport packaging (outer packaging) for building materials, etc. 5. Good anti-theft performance, a variety of food can be packed with a large shrink film to avoid loss.6. Good stability, the product will not fall in the packaging film. 7. Good transparency, allowing customers to directly see the packaged goods for customers to choose products. 8. Good economy, heat shrinkable film packaging is often cheap and with good quality.

Production and application of heat shrinkable packaging

Heat shrink packaging is a very promising form of packaging. At present, there have been cases of using heat shrink packaging to completely replace carton or half-pallet carton. However, due to the immaturity of the current domestic logistics environment, there are some obstacles to the domestic development of heat shrink technology. It is expected that heat shrink packaging will develop rapidly in 3 to 5 years.

The food industry is the largest market for heat shrink packaging. Heat shrinkable film is widely used in the packaging of various fast foods, lactic acid foods, beverages, snacks, beer cans, various alcohols, agricultural and sideline products, dry foods, local specialties, etc. Applications in non-food fields are also increasing, such as labels and caps, seals, fibers and clothing, aerosol products, sports goods, electrical appliances, cosmetics, pharmaceuticals, grease, detergents, stationery, toys, office supplies, kitchen supplies, daily necessities, sundry goods, construction materials, etc.

Shrink film wrapper machineshave different classifications according to different categories. According to the difference of the film, it can be divided into “ pe” film shrink wrap machines and “pof” shrink wrap machines. According to the size of the machine, it can also be divided into fixed shrink film packaging machine and hand-held shrink wrap machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!