Heat shrinkable film packaging materials

At first, The PVC shrink film was the main one. With the continuous development of market demand, PVC shrink film gradually decreased, and various PE, PP, PET, PVDC, POF, PO, etc. became the mainstream of the market.

1.PVC:The PVC heat shrinkable film is produced by polymerizing vinyl chloride monomer into polyvinyl chloride resin and then chemically modifying the polyvinyl chloride resin to produce the PVC heat shrinkable film by blow molding or calendering method. The PVC shrink film has good transparency and high shrinkage. Moreover, the cost is low, the tensile strength is large, the temperature shrinkage range is large, and the requirement on the heat source is not high. However, The PVC shrink film has poor environmental protection and is difficult to recycle. Toxic gases are produced during combustion, which is not conducive to environmental protection. It has been banned in Europe and Japan. China's environmental protection requirements are not very high, and the market sales situation is relatively good. PVC is still the most important material in the field of heat shrinkable labels.

2.PVDC:PVDC is a non-toxic, odorless, safe and reliable high barrier material. In addition to the general properties of plasticity, it also has oil resistance, corrosion resistance, taste retention, and a little moisture and mildew resistance. It can directly contact food. It also has excellent printability. PVDC is mainly used for packaging cold meat. The packaging of cold and fresh meat is achieved by using a vacuum packaging machine. Taking advantage of its high shrinkage and high barrier properties, the packaged cold meat not only has a good appearance, but also keeps fresh for a long time.

3.PET:The PET film is an internationally recognized environmentally friendly heat shrinkable film material. Polyester heat shrinkable film is a new type of heat shrinkable packaging material. The main features of the PET heat shrinkable film are: good shrinkage at low temperature, high shrinkage rate, fast shrinkage, five poisons during combustion and low fever. The PET heat shrinkable film also has high transparency, gloss and excellent heat sealability, suitable for high-speed packaging equipment, with good packaging effect, low cost, non-toxic and harmless.

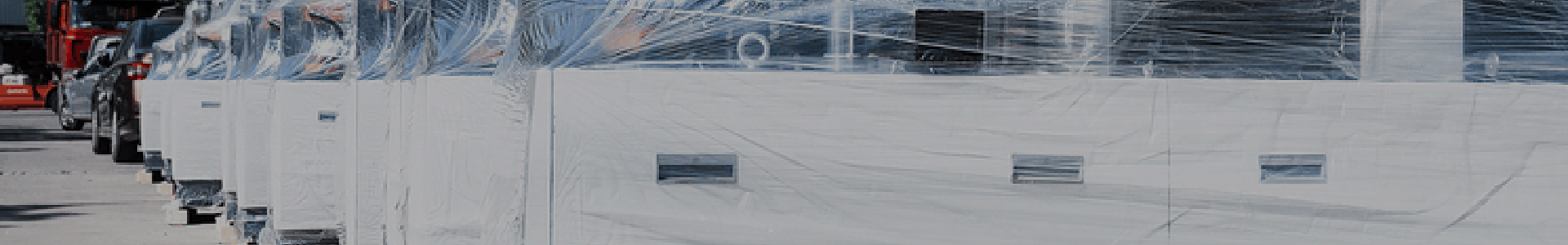

Application in coal machinery packaging

For large products or a large number of single-piece products, you can use a hand-held shrink wrapper machine. This method of operation is simple, fast and economical. For small equipment, desktop shrink film wrapper machines can be used together to save costs.

How on-site heat shrink packaging works: a) Put the pre-cut negative heat shrink film and vapor phase anti-rust film on the bottom bracket in order, and then hang the entire device on the bottom bracket. b) After placing an appropriate amount of desiccant, cover the upper gas phase anti-rust film, wrap it and fix the gas phase anti-rust film with a stretch protective film. c) Use a portable heat shrink packaging machine to heat the heat shrink film evenly to shrink the film, and the film will shrink and adhere to the surface of the device. d) Use strapping straps to securely fix the device to the bottom bracket. e) Cover the top heat shrinkable film and trim it properly, then use a portable heat shrinkable packaging machine to collect the top heat shrinkable film.

If exported in batches, film bags can be made in advance according to the size of the equipment, which not only shortens the packaging time, but also reduces the cost of packaging materials.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!